Can Pipe Relining Save Me Money?

It’s no secret owning a home or commercial property means taking care of the plumbing, yet it’s easy to forget about some of the most essential aspects. So much of what makes up the plumbing is underground, and often it becomes an “out of sight, out of mind” issue.

Plumbing problems range from backed-up sewers to water line breaks, leaks, and minor issues like slow drains. Some plumbing issues, like odors, are often ignored and overlooked, however it’s always recommended to consult a team of professional plumbers to determine the cause of any plumbing issue.

Today we’ll explore how pipe relining could be a solution to your plumbing problems – we’ll cover what it is, the benefits, and explore if it can save you money in the long run.

What Is Pipe Relining?

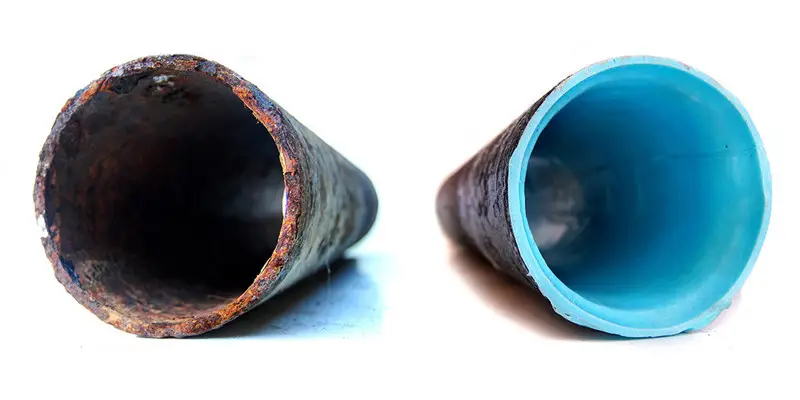

Relining plumbing pipes is a modern and effective method to repair damaged or deteriorating underground pipes. It is an alternative to traditional pipe replacement, typically involving digging up the old pipe and installing a new one, causing disruption and often high costs. Sometimes relining is also called trenchless relining or cured-in-place piping (CIPP). As the name trenchless implies, this technique doesn’t require extensive excavation.

When plumbing piping first emerged, most (if not at all) were constructed of clay. Though this material worked for a long time, PVC pipe became popular in the 1980s. In South Florida, many issues present problems for the sewer systems, and one primary concern is the age of plumbing. Homes built before 1972 will likely still have older pipes (like the Orangeburg pipe) and may need replacement. In other cases as with cast iron pipes, older lines can be rescued and restored with relining.

This technique is commonly used for various types of pipes, including sewer lines, stormwater drains, and some water supply lines. It is particularly beneficial in urban areas with restricted access or where excavation could be more practical and desirable. However, it’s essential to have a professional assessment of the specific pipe condition to determine what a suitable repair option may be.

Signs You Need Pipe Relining

While every situation is different, and the needs of each property vary, there are some tell-tale signs it may be time to consider trenchless relining.

- Noticeable clogs or visible rust

- Noisy toilets (gurgling)

- Odors inside or outside

- Dirty water

- Water backup

- Age of pipes

- Tree root damage or a tree that is growing close to the plumbing

The Process of Relining Pipes

During the pipe relining process, a flexible and durable liner made of resin-saturated material (usually fiberglass or epoxy) is inserted into the existing damaged pipe. The liner is then inflated and expanded, conforming to the inner surface of the original line. The resin is then cured or hardened, creating a new and structurally sound pipe within the existing one. It is a five-step process that includes the following:

- Inspection

- Cleaning

- Measurement

- Curing

- Reconnection

Let’s walk through each step.

Inspection

Before starting the pipe relining process, technicians will thoroughly inspect the damaged pipe using specialized cameras or CCTV equipment. This inspection helps identify the extent and location of the damage, whether it’s due to cracks, leaks, root intrusion, or other issues.

Cleaning

The damaged pipe is cleaned and cleared of any debris, roots, or obstructions. High-pressure water jetting or mechanical cleaning tools may be used for this purpose to ensure a clean and smooth inner surface.

Measurement and Preparation

Precise measurements of the pipe’s length and diameter are taken to determine the appropriate length and size of the liner required for relining. A flexible liner made of resin material (such as fiberglass or epoxy) is cut to the appropriate size.

Inflation and curing

For this step, technicians use existing access places like manholes to insert the liner into the damaged pipe. In some cases, an inflatable bladder may be used to guide the liner through the pipe and ensure proper placement.

Once the liner is in position, an inflation device is used to expand the liner against the inner walls of the original pipe. This process molds the liner to the shape of the existing pipe. At this stage, the liner is also saturated before insertion with the resin to bond it securely to the damaged pipe.

The resin-coated liner is allowed to cure and harden. The time it takes to cure varies based on the resin used and the pipe size.

Reconnection

After the curing process is complete, another inspection is carried out to ensure that the relining was successful and that there are no defects or misalignments. Once the relining is confirmed to be effective, any necessary reconnections are made, and the access points are sealed. The area around the repaired pipe is then restored, leaving minimal disruption to the surrounding environment.

How Long Does Pipe Relining Last?

In general, pipe relining can last for several decades – the longevity does vary depending on the type of liner material used, the original pipe’s condition, and the installation’s quality. When properly installed, it can provide a durable and long-lasting solution (up to 50 years) for damaged pipes. Some factors that can influence the lifespan include:

Pipe condition: The extent of the original pipe’s damage and deterioration can affect the performance of the relined pipe. If the original pipe is severely compromised or has structural issues, it may impact the effectiveness and longevity of the relined pipes.

Installation quality: Proper installation is critical. Experienced and skilled professionals should carry out the installation to ensure the liner is correctly positioned and securely bonded to the original pipe.

Weather conditions and external factors: The location’s weather conditions can also influence its lifespan. External factors such as soil conditions, chemical exposure, and temperature variations can impact the liner’s performance over time.

Maintenance: Regular maintenance and inspections of the relined pipe can help identify and address any potential issues early on, contributing to the longevity of the repair.

Can Pipe Relining Save Me Money?

Like all things home repair, the answer depends on different details, but in general, relining can save money. The technique has several cost-saving advantages over traditional pipe replacement, including minimal excavation, faster repair, seamless installation, and a long-lasting solution.

Trenchless relining requires only small access points to insert the liner, reducing the need for extensive digging and minimizing disruption to landscapes, roads, or buildings. Because of this, you won’t have the expense of a major excavation or landscaping repair costs. In addition to this cost-saving benefit of relining, you’ll also save on labor and equipment costs.

Beyond cost, perhaps the biggest advantage is the time it takes to complete. Relining plumbing pipes is faster when compared to traditional methods, meaning less downtime and inconvenience for property owners and residents. Part of the reason for the quicker completion time is the seamless installation. Since the liner adheres to the surface of the original interior of the pipe, there are no joints or seams, meaning less time is involved.

Finally, pipe relining is a long-lasting solution, similar to property investment. The liner material used is durable and corrosion-resistant, providing a long-lasting and reliable solution to pipe problems.

Art Plumbing, Air Conditioning, & Electric: Trusted Plumbing Experts in South Florida

With Art, you’re getting a team of dedicated, professional technicians who are fully licensed and insured in the latest plumbing techniques. Since 1983, South Floridians have trusted Art Plumbing, Air Conditioning, & Electric for all their property maintenance and repair needs. We offer up-front pricing, emergency services, and a 100% satisfaction guarantee. Schedule a service, request a quote, or speak with one of our dedicated team members today.

Schedule Service